QUANTUM LEAP INNOVATIVE PROCESS FOR CASTING

Effective utilization of resources during casting and to improve the quality of casting

Figure 1 various area where 3d printing can be used

The purpose of the study is about the few of the techniques that we can use so that we can effectively utilize all resources in casting process and improve the quality of casting by reducing defects. The Techniques that we can use are

* 3D printing in casting

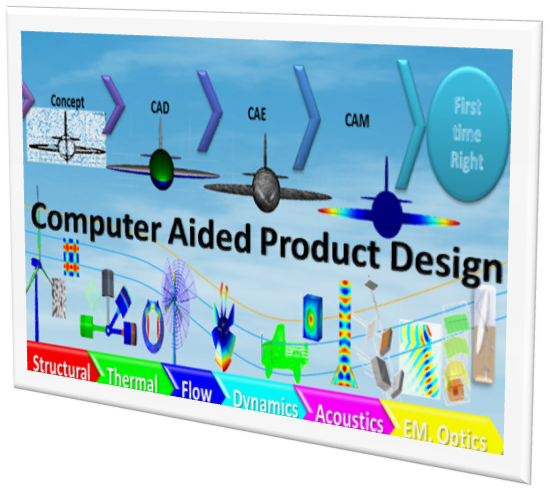

* Multiphysics CAE simulations in casting

* Value stream mapping for effective process planning

* Modular/Flexible molds for casting

We had done certain market analysis on casting and 3D printing to make sure that the ideas are feasible in this present market scenariodriven by heat,

This Internship project is about Innovative process in casting for make in India. Casting is a 6000 years old manufacturing process and it is used until now to manufacture various parts/products, which we use in our daily life. In this Report, a major investigation was done on what is casting and which sector use that more often and a present market scenario of casting in India and some information about 3D printing in relevant to casting. There will be a detailed information about all the four feasible ideas developed.

Business development:

Business development is the creation of long-term value for an organization from customers, markets, and relationships.

Long-Term Value

First, what do I mean by “long-term value?” In its simplest form, “value” is cash, money, the lifeblood of any business (but it can also be access, prestige, or anything else a company seeks in order to grow). In addition, there are plenty of ways to make a quick buck for you or your company. However, business development is not about get-rich-quick schemes and I-win-you-lose tactics that create value that has gone tomorrow as easily as it came today. It is about creating opportunities for that value to persist over the long-term, to keep the floodgates open so that value can flow indefinitely. Thinking about business development

as a means to creating long-term value is the only true way to succeed in consistently growing an organization.

What is casting:

Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Why casting is needed?

* To produce complex components with less costs

* Reducing purchase of machineries

*Parts can be prepared with accurate tolerance limits

* Auto manufacturing sectors is heavily dependent on casting from olden days itself

How casting process can be done innovatively?

*Using Computer Simulations of casting and analysis

*Using 3D printed prototypes for molding

*Process planning

* Good design of prototypes using software

Market overview of casting in India:

2.5.1 The ups and down of foundry market in India:

Expected CAGR: 19.67 (2013-2018)

Some of the significant factors expected to impact foundry market for the next 4 years:

1. Increased need for infrastructure and power generation: (↑)

Power generation markets increase from 4 - 4.2% of total casting in 2013

8.5% of total casting is for sanitary casting requirements in 2013

2. High import duties on metal scrap :(↓)

Government duty – 2.5% import duty on scrap metal

Potential revenue loss of approximately 1.82 billion US dollars to metal casting

manufacturers in India. (This increases their cost of operations)

3. Revival of manufacturing sector :(↑)

Strong demand from domestic and global markets

Ford – US $ 2 billion in India

Renault – Nissan – US $ 2.5 billion in India

4. High Power Requirements :(↓)

Rapid modernization, economic growth & industrialization in India resulted in huge demand

on power grid & large power deficits

Industrial energy requirements of casting:

* Melting metals

* Mold making

* Core making

Objectives

- To improve the quality of casting by reducing defects

- To effective utilize all resources during casting in the world of scarce resources

- To study the present market scenario of foundry industry

- To understand the effectiveness of 3d printing in casting

Figure 2 Types of Materials casted in India

Figure 2 Types of Materials casted in India

Figure 3 Major Sectors contributing to castings

Figure 4 Steps for Metal casting process

{aridoc engine="google" width="900" height="1000"}http://ajf.atoa.com/images/document/5_casting_report.pdf{/aridoc}

DOWNLOAD