HIGH SPEED ROTATIONG IMPELLER

Method for performance computation of an expandable-impeller pump and validated.

Figure 1 Micro gas turbine

Microgasturbines (MGT)– Small Scale power generation system- Similar to Gas Turbine.

•As result of R&D work - Automotive Turbochargers, Auxiliary Power Generating Equipment.

•Electrical Power generation – 25kW to 500kW*. with Stand-alone Power Generation and Combined Heat Power Generation application.

•High Speed Rotation- 160k rpm operational reported. Research Applications - 340k to 400k rpm for micro scale MEMS rotors.

•Operate on Variety of Fuels- Liquid/Gas.

APPLICATION -

Ideal prime movers- Simplicity, Reliability, Fast Response, Low Emissions, and Multi-Fuel Capabilities, Low Maintenance Cost.

Can be used as uninterrupted Power Source in Telecommunications, Restaurant, Residential Buildings, Lodging, Office Building, Food Processing And Variety of Other Commercial Sectors.

Oil and Gas Processing, Coal Mines, Landfills Power generated from the available byproduct gas.

PRINCIPLE-

Single-shaft models generally operate at very high speeds.

•Shaft is supported by Air Bearings or Oil Lubricated Bearings.

•Generates High Frequency Alternative Current (AC), This Power is Rectified to direct current (DC) and then inverted back to required frequency (50-60Hz) of application.

RESEARCH GAP-

From the literature study it is found that there has only little contribution on FSI studies of axial microturbine, where as wider literature support is available for radial microturbine.

•CFD Analysis is more extensive and elaborate than conventional loading calculation using design formulae as given in literatures.

•Natural frequency analysis is essential for high speed rotating rotor shaft.

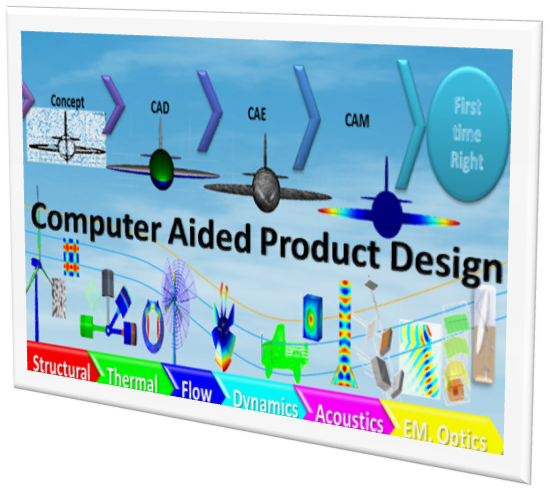

CONCEPTUAL MODELING-

Calculation of Blade Angles, Flow Angles, Stagger Angle, Divergence Angle.

*Calculation of Characteristic Length, Height, Spacing of Rotor And Stator Blades of the turbine.

*Calculation of unknown pressure and temperature.

*Creating 3D model- Bladegen-Blade Editor-Design Modeler.

Meshing for Structural Analysis-

Extracted Fluid Volumes-

Conclusion

- Conceptual Model of axial microturbine is evaluated numerically with CFD analysis

- Under evaluated pressure load, the blades are safe for the given operating speed, with minimal deformation.

- From frequency analysis it is found that the microturbine operating speed selected is safe.

Figure 2 vectorial plot of the flow behaviour over the nozzle and rotor blades

Figure 2 vectorial plot of the flow behaviour over the nozzle and rotor blades

Figure 3 Flow stream lines

Figure 4 Pressure plot

Figure 5 Temperature plot

|

{aridoc engine="google" width="700" height="1000"}http://ajf.atoa.com/images/document/2_HighSpeedImpeller1.pdf{/aridoc} DOWNLOAD |